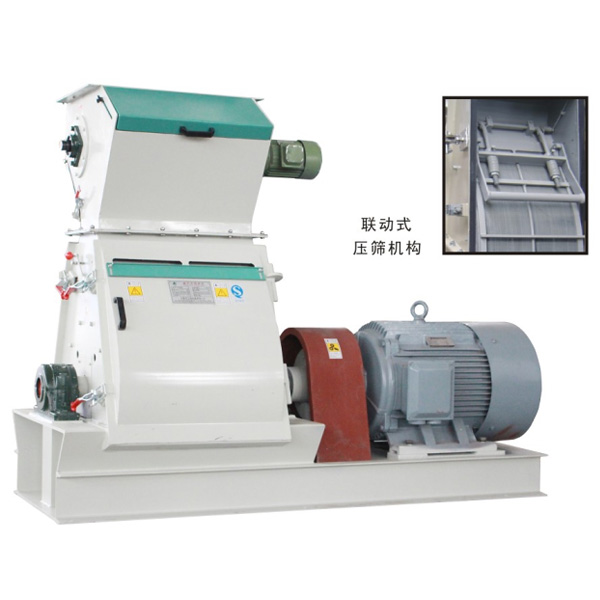

Main features

The crushing chamber achieves a true water droplet shape with a unique air inlet method to avoid circulation during the crushing process; The bottom of the crushing chamber is equipped with a "U" shaped secondary strike groove, greatly increasing production; Quick opening fully open operating door, elastic screen pressing mechanism, convenient for maintenance and replacement of screen pieces;

Adopting imported "NSK" bearings to ensure service life; The nylon rod type coupling is directly driven, compensating for large displacement and effectively avoiding bearing heating.

The rotor has undergone dynamic balance verification to ensure smoother operation, lower noise, and more ideal performance;

The feeding port is located at the top of the crusher and can be matched with various forms of feeding mechanisms;

By adjusting, coarse crushing, fine crushing, and micro crushing can be achieved, achieving multiple uses in one machine.

Suitable for lean farming models such as livestock and poultry feed, aquatic feed, as well as alcohol factories, citric acid factories, etc.