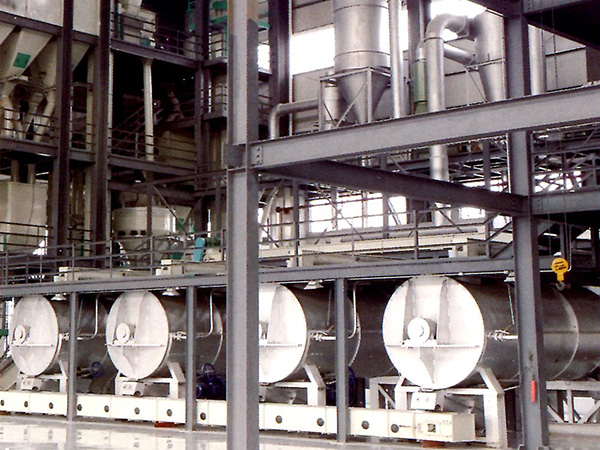

Sharing of usage and maintenance methods for feed machinery

2023-04-26

admin

The new mold pressing wheel needs to be fully and reasonably ground before being officially changed before use. The mold roller of the sawdust particle machine is a heat treated part, and there are some burrs in the inner hole of the mold. The suppression of burrs in the sawdust particles will block the flow of data and shape. Repair and replace parts of the sawdust particle machine. Aluminum veneers have high labor intensity and high load-bearing capacity, and should be continuously tracked for current, voltage, noise, and dust. Then, solutions should be found based on the situation, and faults should be promptly eliminated according to the condition of the joint axle. Defective components should be quickly replaced to ensure the continuity of the production process. The smoothness of the sawdust granulator and the cooling of the pressing wheel. The manufacturer of the feed pellet machine stated that the operating temperature of the aluminum veneer roller is very high, and timely and reasonable oil supply and heat dissipation loss can extend the service life of the roller and improve the production time of the operation roller. The three key points of protective measures for sawdust particle machines, including grinding, repair and replacement of parts, and equipment smoothness, are helpful for the long-term use of the equipment.